Main Second Level Navigation

Feb 15, 2024

Automated and scalable fabrication of heart-on-chip devices

Bioengineering, Research

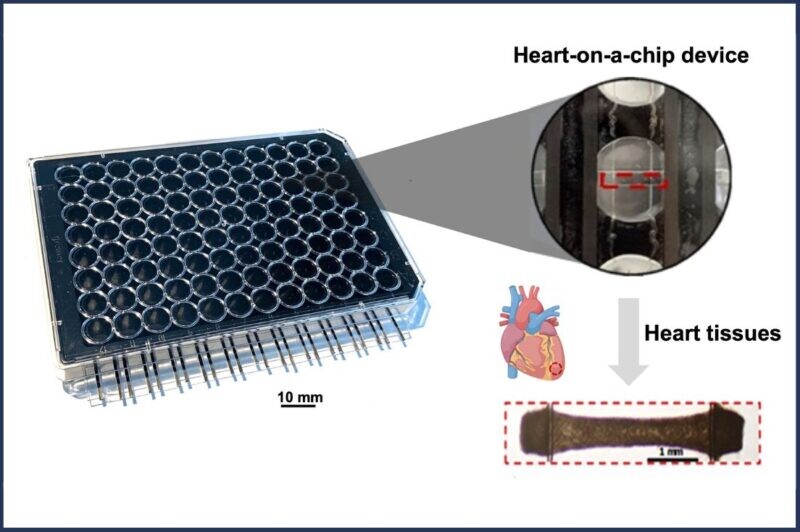

An illustration highlighting some of the key components of the multiwell plate-based heart-on-chip platform: a 96-well plate, the heart-on-chip device in a well, and heart muscle connected by two wires in the heart-on-chip device.